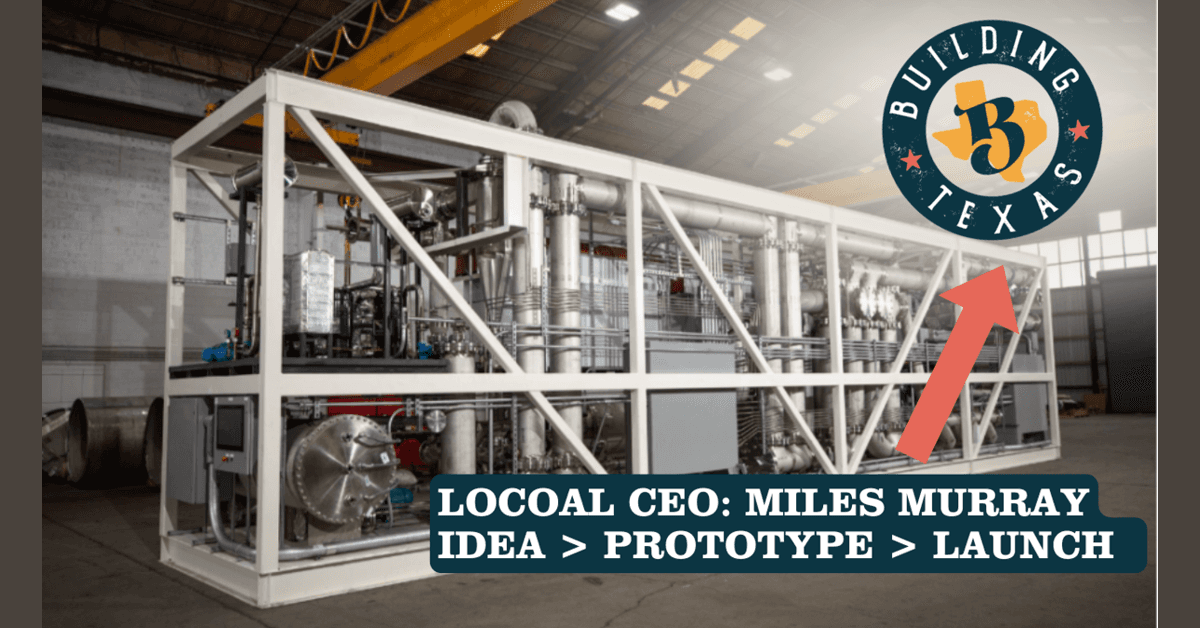

The Building Texas Show recently featured LOCOAL Founder and CEO Miles Murray discussing the company's first commercial full-scale unit installation near Houston. This system transforms organic and rubber waste into clean energy, high-purity bio-carbon, and industrial inputs, representing a new category of mobile modular bioenergy infrastructure designed to make landfills obsolete.

Murray explained that LOCOAL's patented 50-foot system uses thermal decomposition, gas filtration, and bio-oil reclamation to convert materials like wood waste, pallet tailings, storm debris, forestry byproducts, and tires into clean power and sequestered carbon, producing less than 1% ash. "This world continues to compile massive amounts of underutilized resources we call 'trash,'" Murray said. "But there's enormous value inside that waste stream. We've built a system that goes to the source of the problem and turns what was once a cost into a revenue-generating feedstock."

The first commercial pilot is operating at 4840 Solutions, the largest pallet recycler in the country, where it eliminates costly transportation and landfill disposal while producing commodities like clean energy, bio-oil, and high-purity carbon. The technology addresses wildfire mitigation in Texas, where Central Texas is 88% more likely to experience wildfire conditions than national averages, by reducing combustible biomass accumulation while generating market-grade energy and carbon.

Murray noted that agricultural operations, concrete manufacturers, steel producers, filtration companies, and battery researchers are increasingly using high-purity biochar as a critical input for next-generation materials. With over $250 million in letters of intent and $50 million in strategic commitments through Curtis Stout Power, LOCOAL is scaling production for national deployment, supported by a newly issued U.S. patent with protections through 2044. "2026 is the breakout year," Murray said. "We're moving from commercial pilots to full market deployment with buyers and operators across the country. What once was waste will now become a powerful part of the American energy and carbon economy."

The implications for Texas businesses are significant. Companies facing waste disposal costs can transform those expenses into revenue streams while contributing to environmental sustainability. The system's mobility allows deployment at waste sources, reducing transportation emissions and logistics challenges. For industries like agriculture and manufacturing, access to high-purity biochar creates opportunities for product innovation and carbon sequestration. The technology's wildfire mitigation potential addresses a critical safety concern in Texas, where combustible biomass poses ongoing risks. LOCOAL's expansion, backed by substantial financial commitments and patent protection, signals growing market confidence in waste-to-value technologies that could reshape how Texas manages resources and generates energy.